How Rixin Ensure Premium Quality

01. Design Thoughtfully

Design thoughtfully is fundamental for building top quality wooden toys. If the toy design is with flaws in the first place, then there’s no way to make a good quality toy out of it.

Design thoughtfully starts with listening. In order to deliver the toys our customers want exactly, we’ll listen to our customers carefully about their intentions and needs and make sure we get the full idea.

For each specific toy, every possible way (engineering solution, materials choice, printing methods choice, etc.) of producing it are well thought out in the design stage, and we’ll choose the solution which is the most technically reasonable yet fullfills our customers’ needs.

02. Instruction Manual & QC Checklist

Before massive production, we’ll make prototypes and pre-production samples. In the process of making them, we’ll know in which parts quality problems are likely to happen or which parts should be paid special attention to in order to avoid quality problems. These points will be included in the instruction manual, which will be used to guide the massive production later. And they’ll also be included in the quality inspector’s checklist for him to perform the quality inspections.

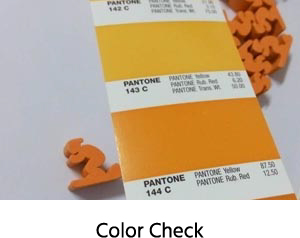

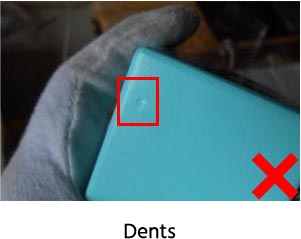

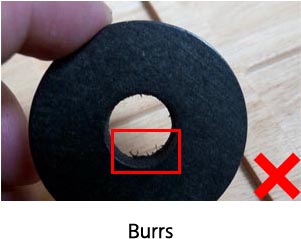

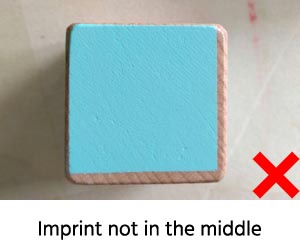

03. Quality Inspections

Instead of doing just one quality inspection in the final assembly stage, Rixin undertake multiple quality inspections throught the entire production process, including shaping blank, painting, printing, and assembly to ensure only the good quality toys are shipped.