Production Process

01. Air Drying

The raw material – wooden boards – will be stacked in the open air to dry naturally before we do anything to them. We’ll only start making wooden toys with them till the moisture content of the wood falls below 15 percent, which is essential for preventing the wooden toys from getting mildewed.

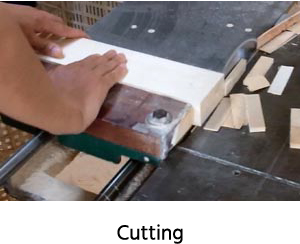

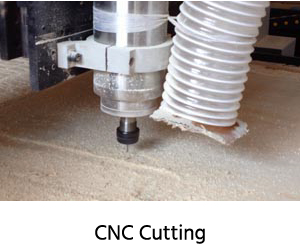

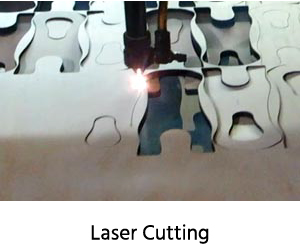

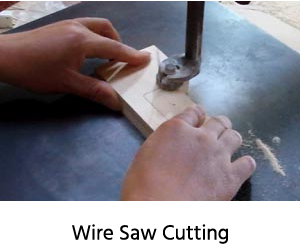

02. Shaping Blank

The process of cutting raw timber into smaller pieces in approperiate sizes and then making them to the shapes of the toys. These uncolored shapes are called “blanks”.

Techniques: wire saw cutting, CNC cutting, laser cutting, die cutting, drilling etc.

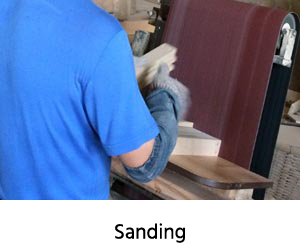

03. Sanding

All blank wooden toy pieces should go though a sanding process to get rid of all the burs and be perfectly smooth for the folllowing coating process.

Techniques: manual sanding, drum sanding.

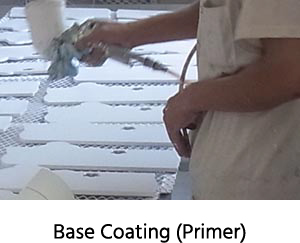

04. Coating

When all the blank wooden toy pieces are smooth and clean, they’re ready for the coating (or painting) process. All of Rixin’s toys have more than one layer of coating to ensure nice finish and good adhesion. First, it’s base coating, or primer, after the primer layer is finished, we’ll sand the toys pieces again to make sure the coating surface is perfectly smooth, then we do the second layer of coating. After each layer of coating, we’ll need to sand the pieces for the next layer of coating, until the final layer of finish is done.

Techniques: spray painting, drum painting.

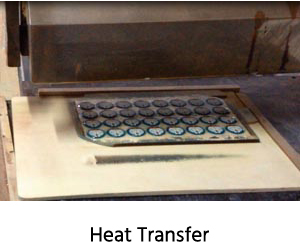

05. Printing

We employ various different techniques to print the colorful images onto the wooden toys.

Techniques: silk screen, heat transfer, pad printing, water transfer

06. Engraving

We can also make elegant engraved logos or images onto the wooden toys.

Techniques: hot stamp, laser engraving

07. Hand Painting

If you want the toys to have an original, unique style, maybe hand painting is the perfect way to do the artworks on the toys.

Techniques: hand painting